Summary

This article describes how to test most accelerometer-based monitoring systems to verify proper installation and operation, and to identify the problems that most commonly occur. In many installations and sensors, issues can be detected by measuring the bias voltage of the sensor, BIAS voltage can be the indicator of cable faults & sensor failures. It’s possible to trend and alarm on the BIAS voltage of accelerometers in most online systems. FFT & time waveform analyses can also be used to identify some of the basic installation and connection related problems in an accelerometer system.

Details

Vibration signal components

AC component

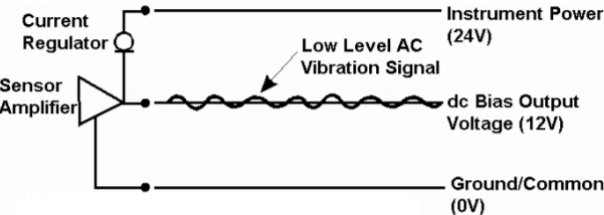

The accelerometer's sensed output is an AC signal proportional to the vibration applied. This AC signal is superimposed on a DC bias voltage, also referred to as Bias Output Voltage (BOV) or sometimes rest voltage.

DC component

Bias output voltages are a common characteristic of sensors used to carry dynamic AC signals to a data acquisition device, vibration and (dynamic) pressure being two common examples. The sensors are powered by an external DC power supply, monitoring system or data collector, typically in the range 18-30 VDC, which supply a constant current to the sensor. The accelerometer circuit design establishes this voltage (or “biases” the voltage) to a preset level. This BOV is normally 12 VDC, although it may vary depending on the manufacturer and the sensor design, refer to the sensor datasheet for confirmation.

- The BOV is determined by the sensor design and is normally not adjustable.

- The BOV remains the same regardless of the power input to the accelerometer, provided it is within the specified range. For example, even if the supply voltage varies from 18 VDC to 24 VDC, The BOV should be 12 VDC in ideal conditions, for a sensor that is functioning normally.

The BOV should be measured periodically to check sensor operation. Manually, a voltmeter measuring DCV will easily measure the BOV and most portable data collectors can also measure the BOV if the sensor is powered by them. The BOV can be trended with many online systems. Trending the BOV provides a record of sensor operation. If the sensor is disconnected or slowly develops a fault, the BOV data can show when the event occurred.

Analyzing BOV for fault indication

Bias equals the supply voltage (18 to 30 VDC): Open, bias fault

When the measured BOV equals the supply voltage, this is an indication that the sensor is disconnected or reverse powered. In most cases the problem is the connector or cabling.

- First check the cable termination at the junction box, data collector or monitoring system. If the cable is connected to a terminal block, make sure the wires are secure and are in the proper terminals.

- Next check the cable connection to the sensor. Often the sensor may have been disconnected for maintenance and never reconnected. If a faulty connector is detected, it can be disassembled or replaced, but avoid disassembling or removing the connector until all other fault sources have been checked.

- If each end appears good, check all other terminations, splices and connectors. Also ensure that the cable is not crushed or cut somewhere along its length.

- If the cable and connections appear good, further test the cable continuity. Cable continuity can be tested by shorting the signal leads at one end of the cable to the shield wire and measuring the resistances at the opposite end. Depending on the cable length, several ohms to no more than several hundred ohms should be measured from each wire to the shield.

- If the cable and all connections are in proper working order the fault is in the sensor. However, note that open faults internal to the sensor are very uncommon compared to cable/connection faults.

Bias is 0 VDC: Short, bias fault

When the measured BOV measures zero volts, power failure or a system short is usually the problem.

- First ensure that power is turned on and connected.

- If the power supply is on, check for a short in the cabling. Like the open fault, it is very rare to have a short inside the sensor, the most common fault location is in junction box terminations.

- Check to make sure that a frayed shield is not shorting across the signal leads.

- Often a damaged cable can produce a short. To check the whole length of cable and identify what might be shorted, disconnect it from all other devices leaving both ends 'open'. Then confirm electrical isolation by, at one end, measuring resistance between all signal leads and shields (for example that would be 3 measurements for 2 signal wires and one shield). The resistance measured by the ohmmeter or digital multi-meter should be infinite or as a minimum, greater than 50 megaohms.

Low bias, high bias: Damaged sensor

Out of specification bias readings other than the two extreme cases described above, usually indicate sensor damage. Common sources of sensor damage are:

- Exposure to excessive temperature.

- Shock impacts.

- Having being powered incorrectly.

- Electrostatic discharge damage.

Excessive temperature is the most common cause of sensor failure.

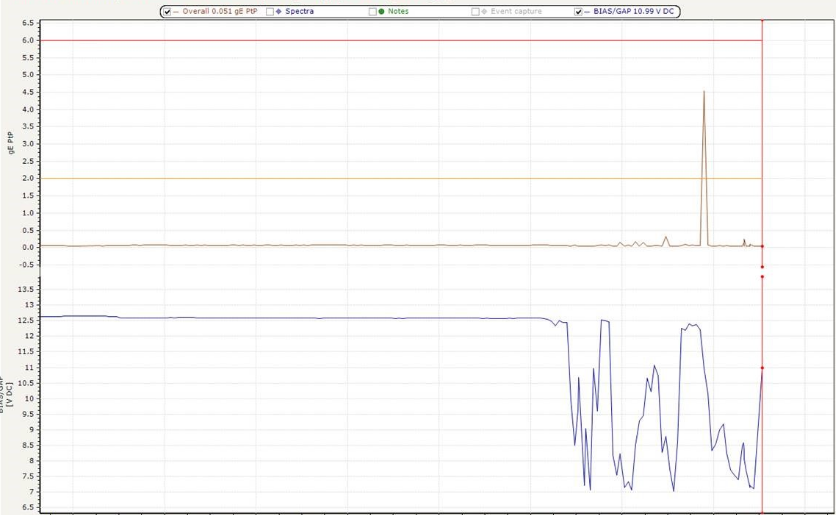

Sensors caught in a fire are usually destroyed and can show various bias readings depending on the failure mode within the sensor. Long term temperature failures are characterized by a slowly rising or declining bias voltage (lower trace in the example shown below):

In many cases the bias can return towards normal as the temperature decreases, however, the damage to the amplifier is permanent and the sensor may continue to deteriorate. As in the upper trace of the figure above, (a sensor failing from long term temperature degradation in a paper machine dryer section), this degradation will also affect the vibration trend.

Erratic bias and time waveform

The bias voltage should remain stable and unchanging for properly functioning sensors. A shifting bias indicates a very low frequency signal that is being assessed as a change in the DC level. In rare cases this indicates an actual low frequency signal, however, in most cases this indicates a fault. Primary causes of erratic bias are

- Thermal transients.

- Poor connections.

- Ground loops.

- Signal overload.

Each of these faults will also be visible in the time waveform as erratic jumping or spiking of the signal. Thermal transients cause uneven thermal expansion of the sensor housing materials. This can be sensed by the sensor as being a low frequency signal and is most evident when using low frequency sensors. Poor or contaminated connections can also cause low frequency bias and contact noise:

- Check for corroded, dirty, or loose connections.

- Repair or replace the connection as necessary.

- Non-conducting. silicone grease should always be applied to connectors to reduce contamination.

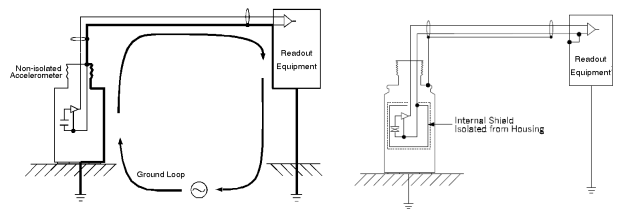

Ground loops are developed when the cable shield is grounded at two points of differing potential:

- Always ground the shield at one end only!

- An easy test for ground loops is to disconnect the shield at one end of the cable, if the problem disappears it was probably a ground loop fault.

When reviewing the measurement loop(s), consider the whole system including whether isolated or non-isolated sensors are used, shield and equipment ground connections, any intermediate junction boxes. The image below compares a system connection arrangement susceptible to ground loops (left) with a correct installation where no loop is formed (right):

Sometimes spurious spikes from fast thermal shifts, lightning strikes, and shocks can overload the sensor and cause a momentary shift in the bias voltage. The shift in bias can trigger alarms and protection system shutdown devices. To prevent this, a longer delay can usually be programmed or hardwired into the monitoring system. The delay prevents the system from taking action until the sensor has settled.

High frequency, high amplitude vibration signals can also overload the sensor and in severe cases cause bias shift and erratic time waveforms. However, overload problems are usually detected by observing truncated waveforms and large ski-slope spectra.

Time waveform for sensor fault analysis

The time waveform of a sensor output can be viewed with an oscilloscope, most data collectors and online vibration monitoring systems. Reviewing the time waveform can immediately indicate a clipped signal, which usually looks truncated or flattened on one side and normal on the other. Severely clipped signals will cause the waveform to look jumpy. Poor connections can also cause a similar jumpy reading.

- A clipped signal is where the output can no longer faithfully reflect the measured parameter because it cannot be driven high or low enough and is 'clipped' at a limit value, the amplifier has 'saturated'.

It follows that using an 18-volt power supply and a 12-volt bias, clipping will occur sooner than if a 24-volt power supply were used. Therefore, one potential method to reduce the likelihood of clipping is to use a higher power supply voltage and ensure that the bias voltage is centered between supply voltage and ground. This may not often be a practical solution however, as the bias voltage and power supply are rarely adjustable. The easiest solution is to use a lower sensitivity sensor.

Due to capacitive effects, long cables in excess of 60 m / 200 feet can attenuate amplitudes at high frequencies and may be problematic in some applications.

FFT spectrum for sensor fault analysis

An FFT spectrum can give another quick indication of signal quality. The one-times (1X) operating speed vibration is usually present and a good indication of proper operation. If the time and frequency measurements read zero, the sensor is disconnected or is not functioning.

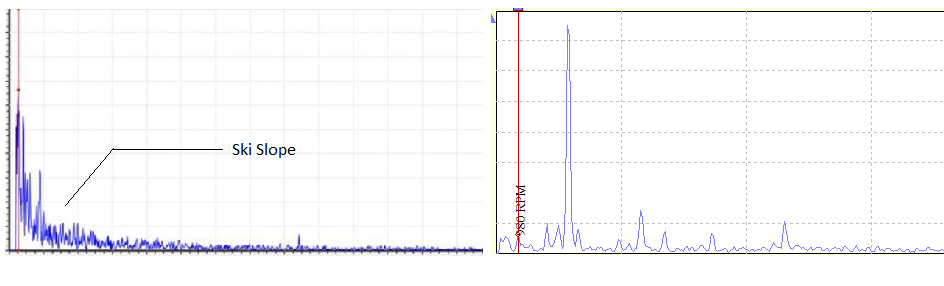

Ski slope

The presence of a large ski slope can indicate distortion from sensor overload. However, a noisy accelerometer that has been integrated to velocity or displacement may also produce ski-slopes for various reasons.

- A ski-slope is where the lowest frequency lines in the FFT have unexpectedly high (often the highest) amplitudes with that amplitude generally decreasing as frequency increases to give the appearance of a 'ski-slope' silhouette:

In a sensor overload situation the ski-slope spectrum occurs because if the amplifier saturates, nonlinearities are introduced and intermodulation distortion occurs. This causes low frequency noise, also referred to as wash-over distortion.

Mounted resonance effects

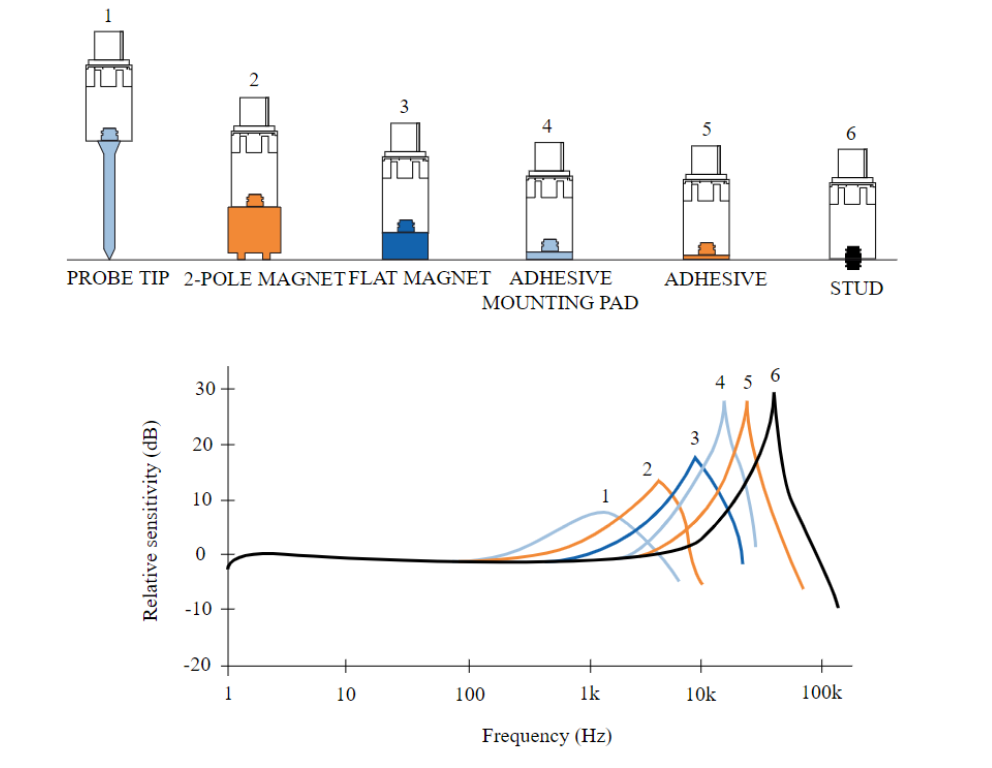

A mounting resonance can give false indication of high frequency machinery faults such as gear mesh and bearing problems. The problem is more likely to occur when using probe tips and magnets, and care must be exercised to prevent the measured mounting resonance peaks from being falsely identified as machine produced peaks. A comparison of mounting methods illustrates the relative effect:

- Mounting the sensor on thin plates such as machine guards, can also lower the mounted resonance

Re-measuring with the sensor mounted at a different location will usually discriminate machine vibration from a mounting resonance. However, if a machine signal coincides with a sensor mounting resonance, a greatly increased signal can result. This can lead to sensor overload which will be manifested with a spectrum dominated by a ski slope, as described earlier. Some common mechanical causes of a sensor overload are:

- Severe pump cavitation.

- Steam release.

- Impacts from loose or reciprocating parts and gear meshing.

Line frequency harmonics in spectrum

Harmonics of the prevailing AC line frequency (typically a general industrial supply might be 50 or 60 Hz) usually indicate interference from motors, power lines and other emissive equipment.

- Ensure that the sensor shield is grounded (at one end only).

- If the shielding is good, check the cable routing. A good measurement practice is to run signal cables in cable trays separated from power line cable trays by at least 350 mm.

- If a signal cable tray must come near a power cable tray, they should cross at right angles to reduce the possibility of magnetically coupled signals.

- Using shielded, twisted pair cable will also help minimize any magnetically coupled noise into the signal cable. For example, if a power cable is 440 volts and the vibration signals from the sensor are at the millivolt level, any cross talk will severely corrupt the data.

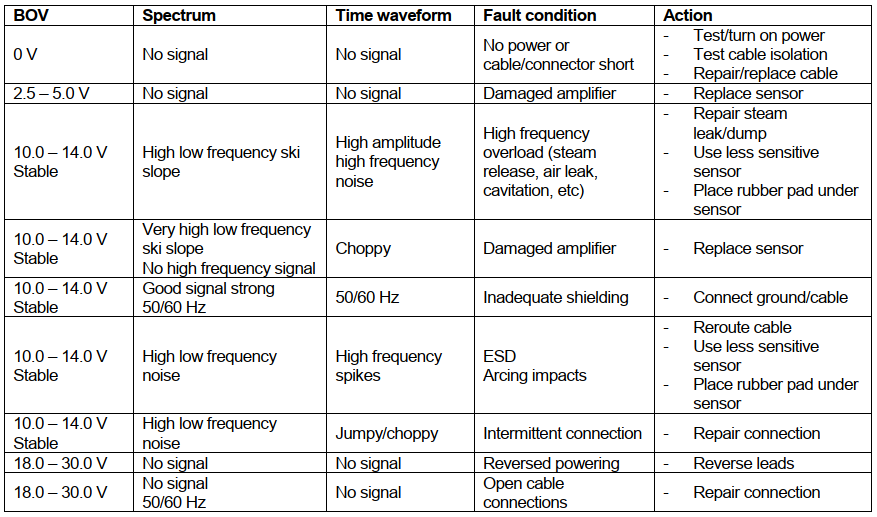

Troubleshooting summary

Shown below is a troubleshooting chart for sensors with a 12 volt bias. For sensors with other bias voltages, the same

concepts apply, only the stable bias range will be different.

Contacting SKF Technical Support Group

For further assistance please open a support case using the Technical Support group's self-help portal at www.skf.com/cm/tsg. Once your support case is submitted, a technician will contact you to begin working on your issue. For urgent issues we are available at these times by phone:

- Monday through Friday, 5:00 a.m. to 4 p.m. Pacific Time -

Phone: +1 800 523 7514 within the US or +1 858 465-45107 outside the US. - Monday through Friday, 8:00 a.m. to 4:00 p.m. Central European Time -

Phone: +46 31 337 65 00. - Monday through Friday, 7:30 a.m. to 4:30 p.m. India Standard Time -

Phone: +60 16 699 9506.

Comments

0 comments

Please sign in to leave a comment.